The Partial Valve Stroke Test (short: PVST)

Enables the operator to check and guarantee the safety of the system without interrupting the process. Here, the valve is only partially closed (by 5% up to around 20%) and thus some of the possible sources of error are tested, especially with safety shut-off valves. The functionality is checked during operation if required without interruption of flow.

What is the purpose of the test?

This process does not affect the ongoing operation but proves the mobility of the valve and thus rules out the most common passive errors. Automated valve start-up tests increase process reliability and system availability and are often also used for maintenance concepts. After the test period has expired, the safety shut-off device is returned to the operating position.

How does SCHUCK implement this test specification?

At SCHUCK, we have offered this valve test with our drive technology for many years via the SEC (Schuck Electronic Control) or, if this extensive control element is not required, via the simpler electronic variant SEP (Schuck Electronic Partial Test).

However, digital control elements are also not completely error-free, and especially in offshore systems where the safety requirements are extremely high, mechanical elements are also used in addition to these electronic positioning elements to manually check the safety valve on site. We have integrated this into our product portfolio with the new in-house development SMP (Schuck Mechanical Partial Test Device).

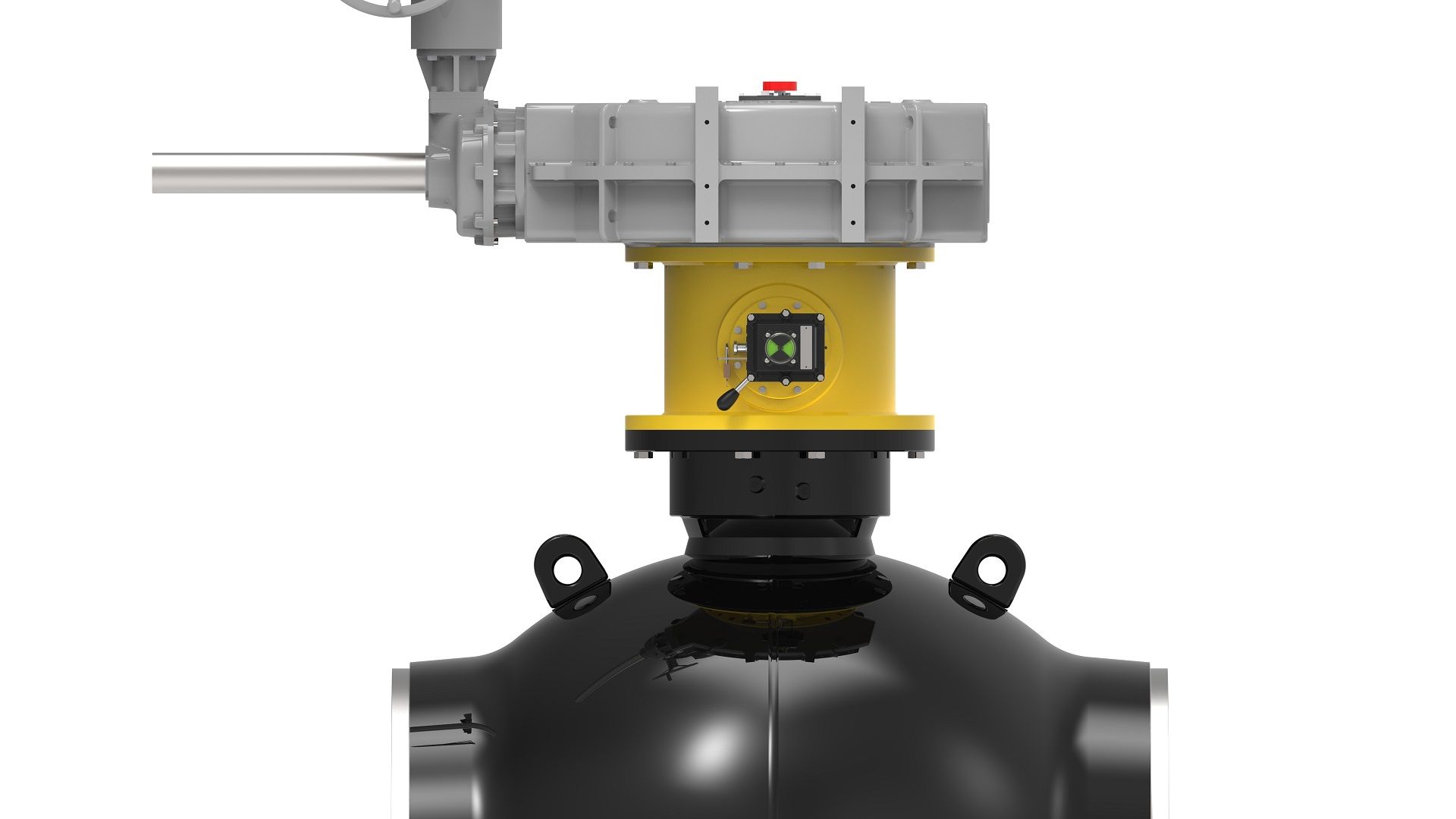

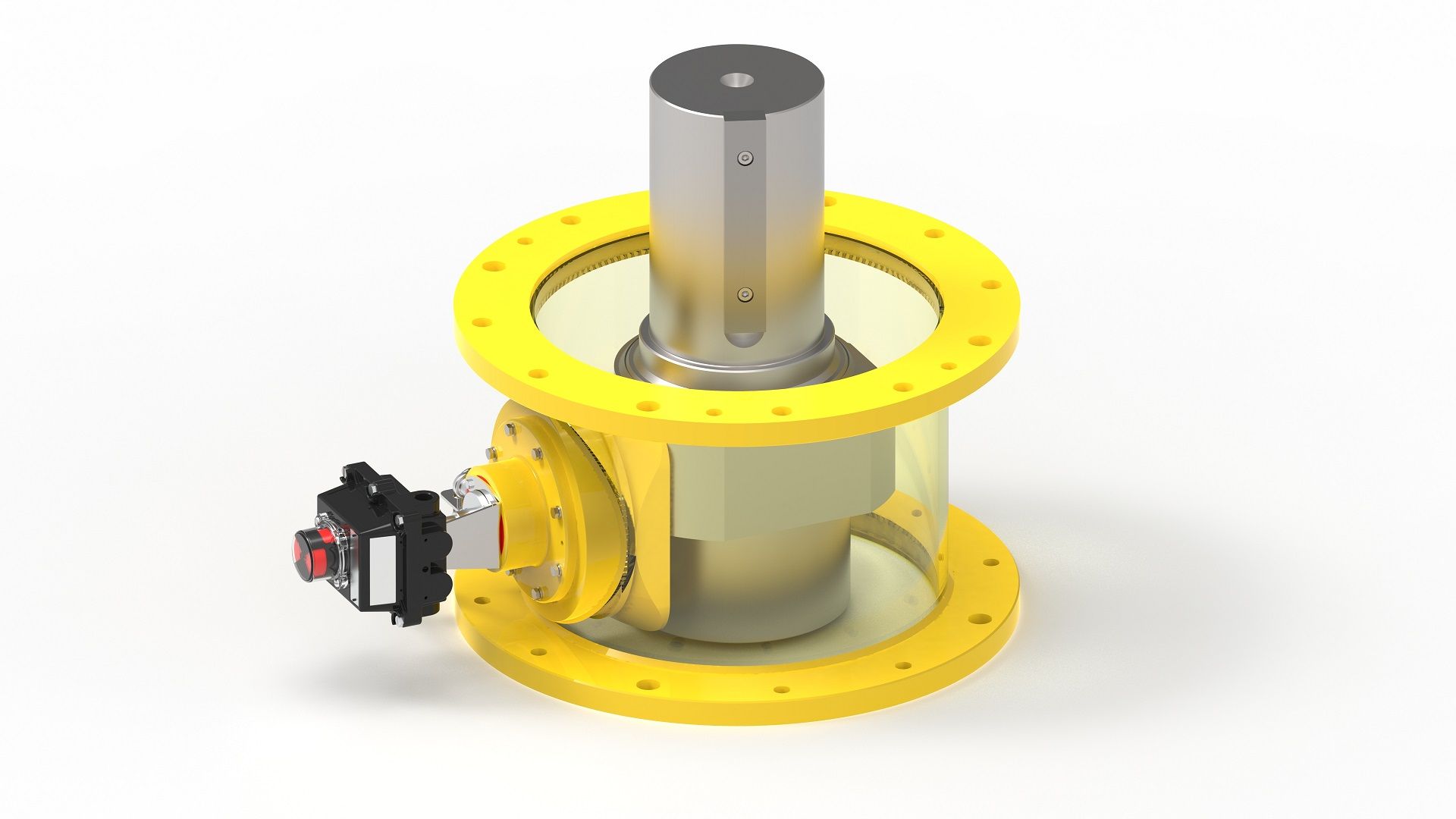

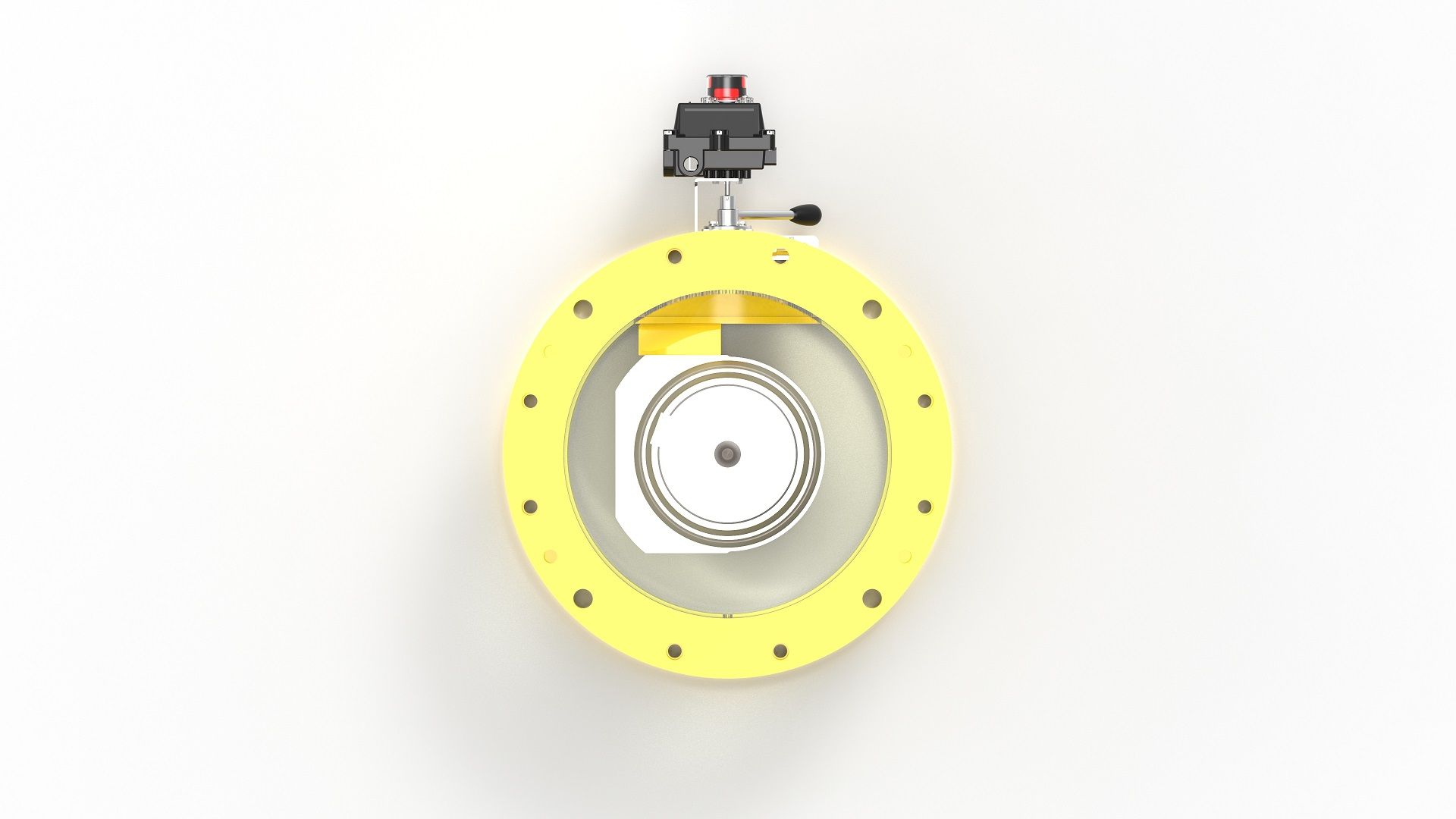

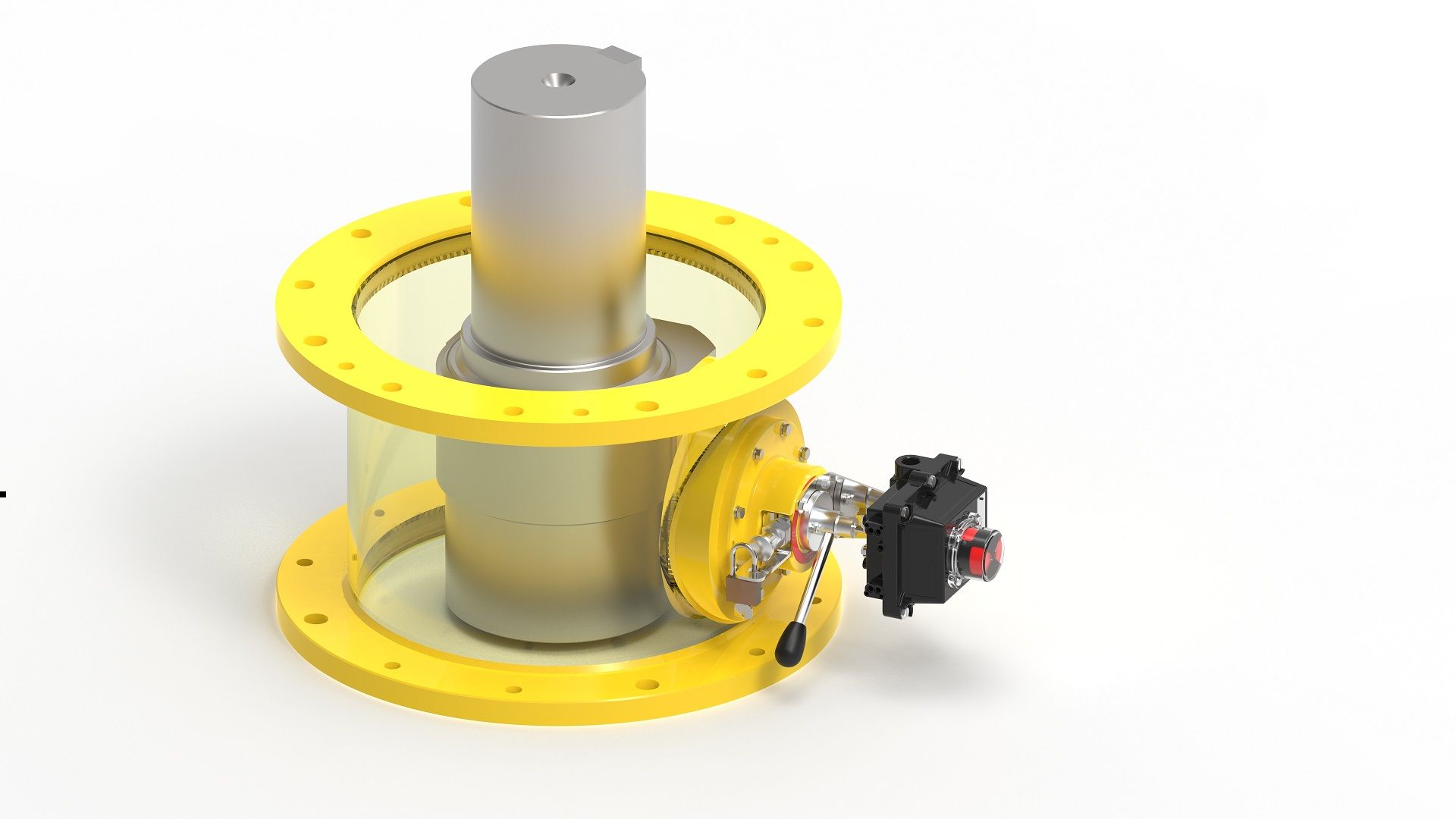

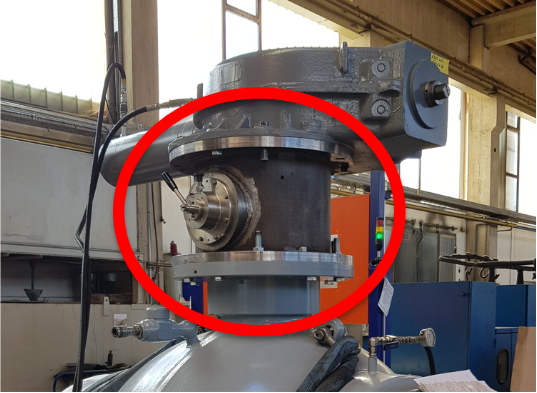

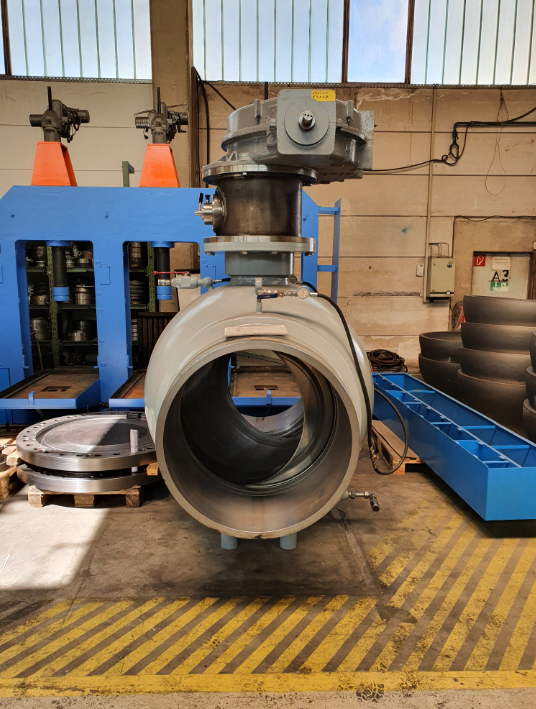

Schuck ball valve in 20% closed position - SMP moved to block

Test procedure in-house development

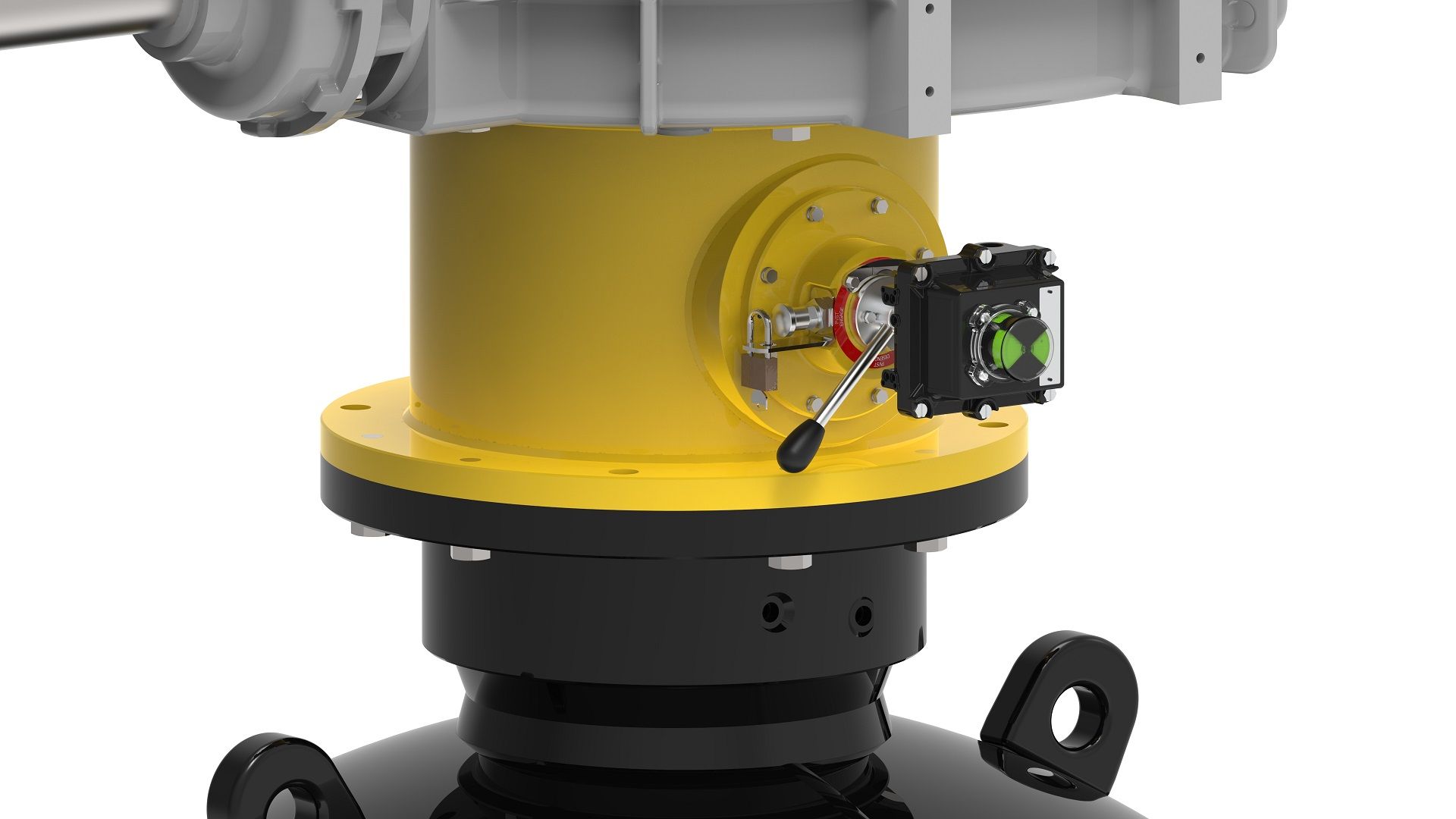

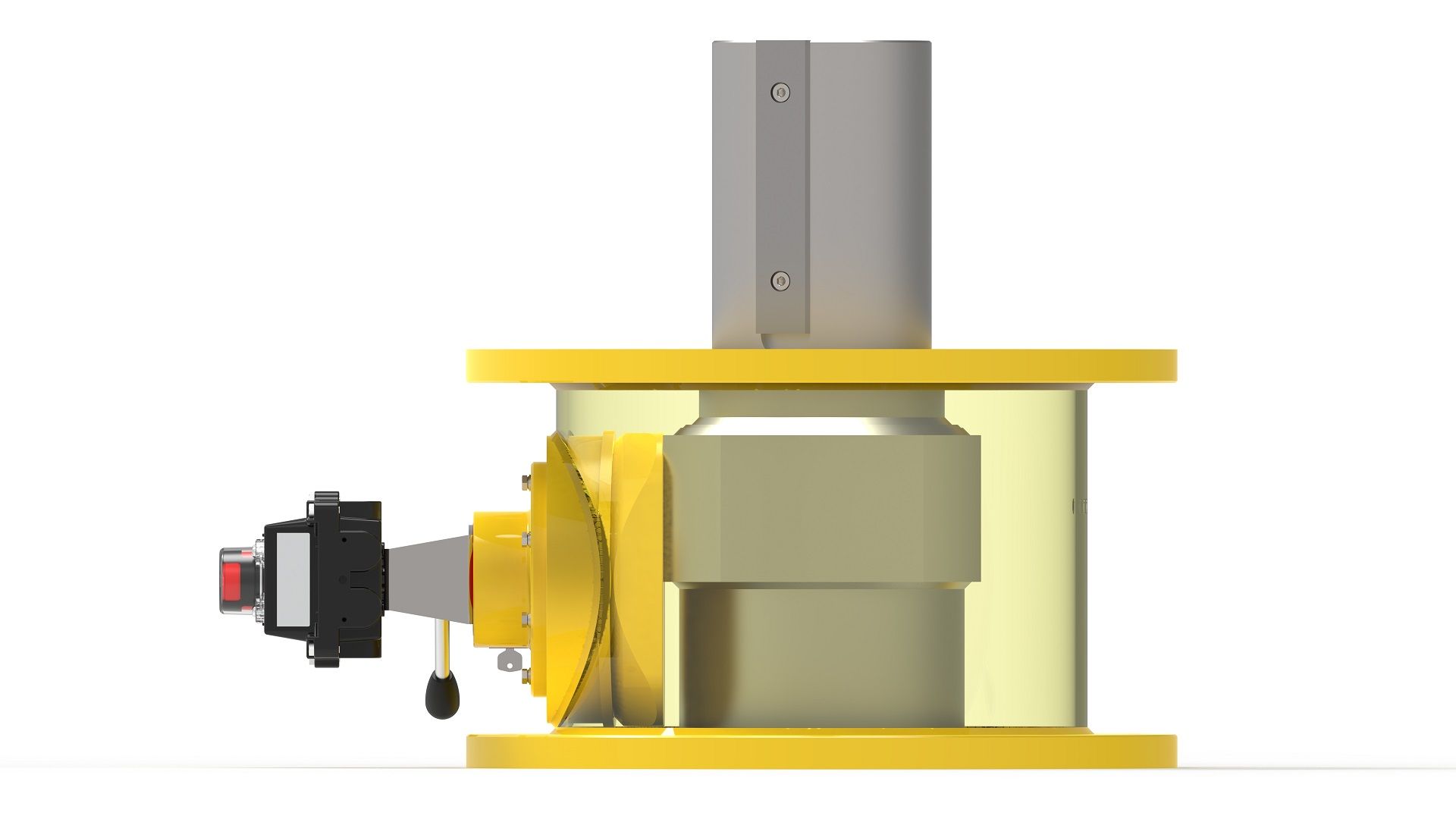

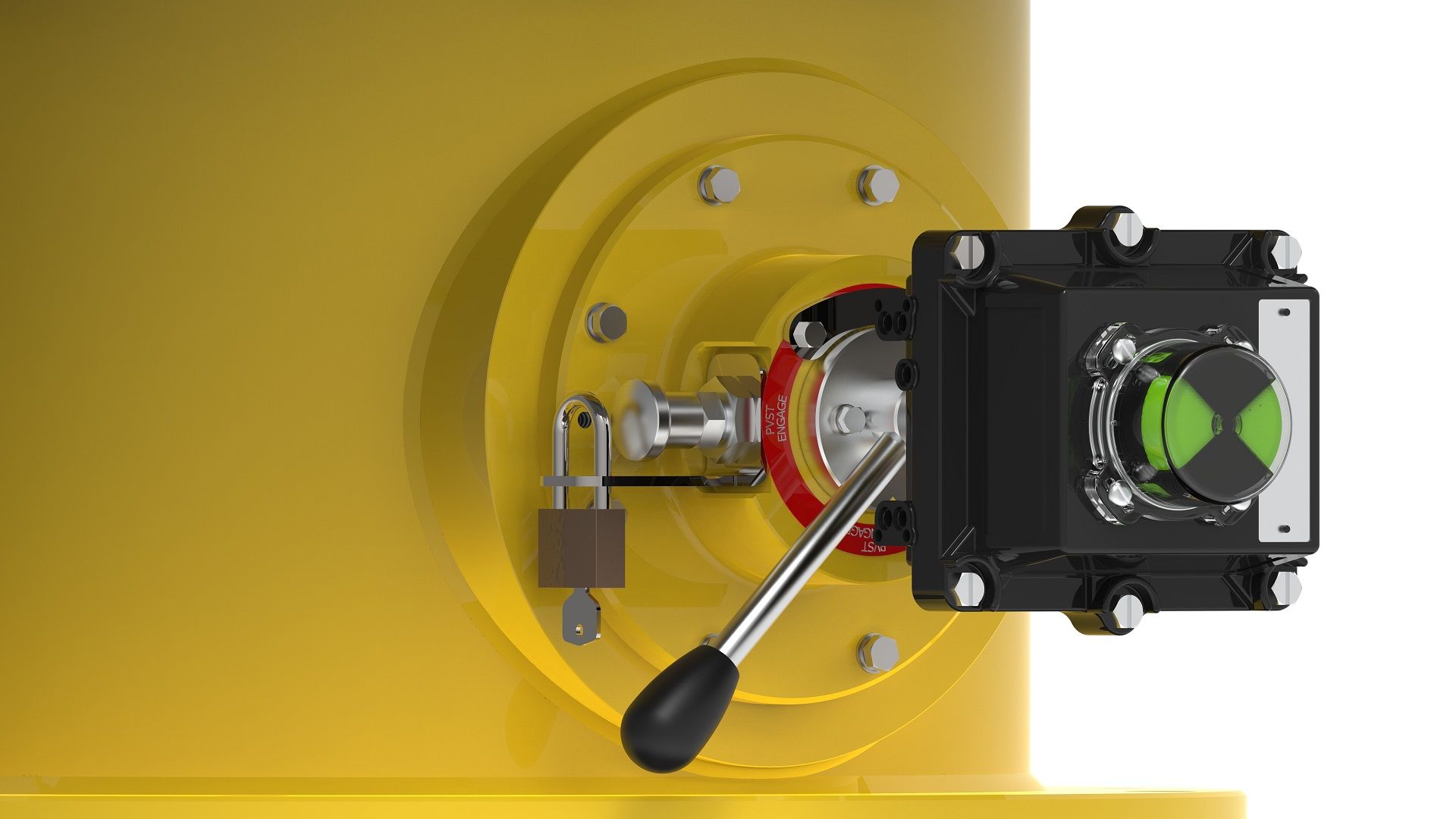

The SMP (Schuck Mechanical Partial Test Device) is installed between the valve and the actuator and, if necessary, is manually unlocked to carry out the PVST. The limitation of the rotation of the valve of approx. 20 ° is already pre-set with a start-up block. Optionally, a position switch is also supplied to document the process in the control room.

This mechanical system is extremely robust and can outperform smart positioning systems with its reliability, as it is practically error-free thanks to its simple block mechanism, even if the operating costs are perhaps a little higher due to the manpower required. However, this reduces the intervals between the system stops to check the safety-relevant fittings many times over, in some cases even from annually to every 5 years.

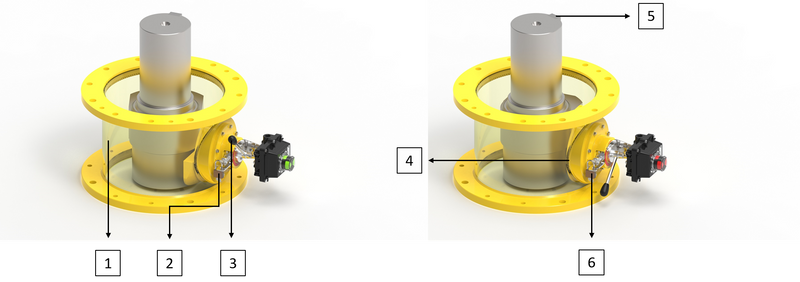

PVST test setup

- Custom console

- The safety pin must be activated to switch the SMP

- Shift lever for engaging and disengaging the SMP starting element

- SMP starting element

- Actuating shaft adapter between valve and actuator

- Locking unit

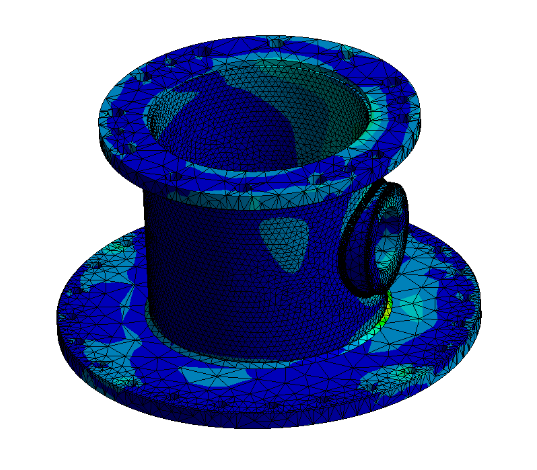

FEM model

During development, we created a FEM model and verified it with the calculations. The only minimal deformations of our in-house development SMP can be clearly seen here. We then built prototypes and successfully tested them in several series of tests.

Photo gallery - The SMP in detail

SMP = Schuck Mechanical Partial Test Device for the PVST (Partial Valve Stroke Test)

Visual inspection of a completed PVST

Passed the test!

The advantages of SCHUCK SMP briefly

- Carbon steel mechanical locking device that can be disengaged

- Limitation of the rotation of the valve / actuator of approx. 20 ° pre-set

- SMP is located between the valve and the actuator

- Self-contained unit

- No stress on the ball valve operating shaft or the actuator yoke

- SMP is lockable

- Optional with limit switch and feedback to the control room

Download & bonus material:

--> Watch Webinar: Remote Actuated Valve Design – Adding Partial Valve Stroke Testing (09/30/2020) on Youtube.

--> Read the information article on Partial Vale Stroke Testing in AutomationForum.co (4 | 2018) here.